Stone plastic waterproof fireproof SPC flooring and wall board

Ourcompanyandourproductshavebeencertificatedby ISO9001 , ISO45001 , CE , SGS , etc.

Waterproof/Anti -slip

SPC flooring features an entirely waterproof core.And it has super anti-skid function to ensure safety.

Wear Resistant

SPC flooring is resistant to scratches and stains. It holds up well to wear and tear even in high-traffic areas of the home.

Anti bacterial

SPC flooring has anti bacteria l function, inhibit mildew, prevent borers .

Fireproof

Through special substrate and surface treatment,super fireproof function is realized to ensure durability.

Easy Installation

SPC flooring is made to be installed on top of just about any type of sub-floor or existing floor as long as it's flat and sound. You won't have to deal with messy glues since the planks easily attach to one another to lock into place .

Superior Elasticity

Excellent substrate treatment allows the product to exhibit good impact resistance, high elasticity and comfortable foot feel.

Easy Clean

You can use a wet rag or mop to wipe itc lean.

Eco - Friendly

Not only it is formaldehyde -free but there is no plasticize inside .

SIZE: 1220×180×5.0mm/Wear Layer Thickness:0. 3mm

SFR-6601

SFR-6602

SFR-6603

SFR-6604

SFR-6605

SFR-6606

SFR-6607

SFR-6608

SIZE: 1220×180×5.0mm/Wear Layer Thickness:0. 3mm

SFR-8101

SFR-6602

SFR-8103

SFR-8104

SFR-8105

SFR-8106

SFR-8107

SFR-8108

SIZE: 1220×180×(6 . 5+1. 5IXPE) mm/Wear Layer Thickness:0.5mm

SFR-8601

SFR-8602

SFR-8603

SFR-8604

SFR-8605

SFR-8606

SIZE:610×305×4 .0mm/Wear Layer Thickness:0 . 3 m m

SFR-8201

SFR-6202

SFR-8203

SFR-8204

SIZE: 610×305×4 .0mm/Wear Layer Thickness:0.3mm

SFR-8201

SFR-6202

SFR-8203

SFR-8204

SIZE:1218×150×(5.5+1. 5IXPE) mm/Wear Layer Thickness: 0.5mm

J6101

J6102

J6103

J6104

J6105

J6106

J6107

J6108

SIZE: 610×305×(5.5+1. 5IXPE) mm/Wear Layer Thickness: 0.5mm

J-6101

J-6102

Herringbone

J-YA6106/SIZE: 648×108×(5.5+1. 5IXPE)/0.5mm J-YB6106/SIZE: 750×125×(5.5+1. 5IXPE)/0 . 5mm

J-YA6107/SIZE: 648×108×(5.5+1. 5IXPE)/0.5mm J-YB6107/SIZE:750×125×(5.5+1. 5IXPE)/0.5mm

J -YA6108/SIZE: 648×108×(5.5+1. 5IXPE)/0.5mm J-YB6108/SIZE:750×125×(5.5+1. 5IXPE)/0.5mm

J-YA6109/SIZE: 648×108×(5.5+1. 5IXPE)/0.5mm J-YB6109/SIZE:750×125×(5.5+1. 5IXPE)/0.5mm

SIZE: 610×305×(5.5+1. 5IXPE) mm/Wear Layer Thickness: 0.5mm

J-6101

J-6102

SPC lock floor, in simple terms, refers to the floor that can be completely free of nails, glue-free, keel-free, and directly laid on the floor during the floor covering process.

The PVC self-adhesive floor (also called LVT, luxury vinyl tile) is coated on the back of the original floor, coated with self-adhesive sticker, and then covered with a PE release film to protect the adhesive. When the floor is installed, the release film can be peeled off by hand to realize convenient and quick installation of the floor.

SPC lock floor and PVC self-adhesive floor are difficult to distinguish from the paving effect. However, there are still some differences in the use process, mainly in the following aspects:

1. The sense of foot comfort is not the same:

The production process and technical requirements of SPC lock floor are relatively high, the thickness of SPC floor is usually about 4mm, which is thicker than the usual 2mm of PVC self-adhesive floor, and the foot feels more comfortable.

2. The installation process is different:

(1) SPC lock floor can be installed by the lock connection between the floors, the paving is simple and fast, and the glue is not needed during the installation process. The worker can install more than 100 square meters per day on average.

(2) The installation of PVC self-adhesive flooring is simpler and faster. The back of the floor comes with pressure-sensitive adhesive. As long as the protective film is torn off, it can be directly attached to the ground.

3. Indoor environmental performance is not the same:

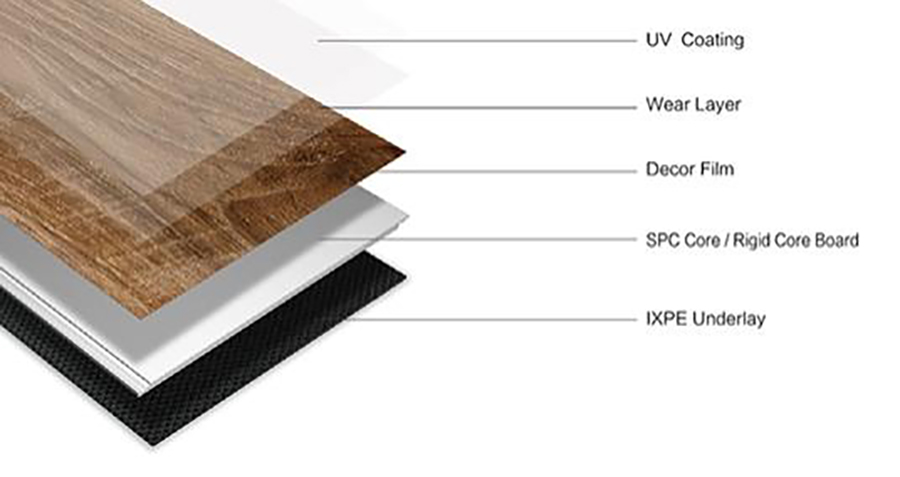

(1) SPC floor structure is composed of: UV coating, pure PVC wear layer, rich color film layer, SPC polymer substrate layer, soft and silent backing layer. The floor substrate is made of mineral rock powder, mixed with polymer resin, and then subjected to high temperature and hot pressing to form a stable substrate layer. It

can achieve true zero formaldehyde.

(2) PVC self-adhesive flooring raw materials are not as high as SPC lock floor, some manufacturers with less strict control, glue may contain a small amount of formaldehyde, there will be certain environmental pollution.

3. Paving flatness is not the same:

(1) The hardness of the SPC lock floor is high, and it is not fixed to the ground by glue when paving. Therefore, the flatness of the ground is required to be high. If the ground is not flat, it usually requires self-leveling before paving.

(2) The PVC self-adhesive floor is soft, and the floor can be paved if there is a gentle undulation, but after the paving, the floor will rise and fall with the original ground. Such higher places are more prone to wear. At the same time, the ground is too rough or dusty sand, and it is easy to cause debonding and edge warping.

4. The scope of application is different:

SPC lock floor is versatile and suitable for most places, such as homes, offices and schools, shopping malls, store rooms, etc., with high wear resistance and long service life. PVC self-adhesive flooring has relatively weak wear resistance and is not suitable for use in places with high traffic.

5. The price is not the same:

The price of the SPC lock floor will be higher than that of the PVC self-adhesive floor, but the service life is longer, and the basic ground requirements during construction are not high, as long as it is flat. The self-adhesive PVC floor has high requirements on the ground, and it needs to be flat and can not afford dust, and at the same time avoid water, as the self-adhesive floor is hot stamped on the floor after high temperature, which is easy to debond and warp.

We made a comparison between SPC floor,LVT and WPC floor as follows.It

helps you make wise choice when selecting floors.ed if there is a gentle undulation, but after the paving, the floor will rise and fall with the original ground. Such higher places are more prone to wear. At the same time, the ground is too rough or dusty sand, and it is easy to cause debonding and edge warping.